Currently, many enterprises under the Shipbuilding Industry Corporation (SBIC) have orders lined up until 2026–2027. However, due to lingering debts from the past and the inability to secure capital for reinvestment and production expansion, many shipbuilding companies have had to regretfully decline new orders.

Implementing Government Resolution No. 220/NQ-CP on the policy of bankruptcy for the parent company – SBIC – and seven subsidiaries, the shipbuilding industry hopes to accelerate bankruptcy procedures and develop criteria so that post-bankruptcy enterprises can retain their industry capabilities, minimize impact, and move forward into a new era — the era of the ocean and the era of the nation.

Part 1: A Surge in Shipbuilding Orders – No Longer Living “Hand to Mouth”

A multitude of ship series of various types are currently being handled by SBIC’s shipbuilding companies. Orders from shipowners are coming in rapidly, but due to limited production capacity, many companies have reluctantly declined to take on more.

Turning Down Orders Despite High Demand

At SBIC shipbuilding companies such as Bach Dang, Nam Trieu, Pha Rung, and Song Cam, the workshops are bustling with the sounds of hammers, cutting machines, grinding tools, and the bright glow of welding torches. Every component of a ship is meticulously crafted by skilled workers.

Currently building a series of 13,000-ton oil/chemical tankers for export to South Korea, Mr. Tran Van Rung, Deputy General Director of Pha Rung Shipbuilding Company, shared that the company is fully booked until 2027. With favorable shipping rates and a strong global shipbuilding market, demand has surged. Major shipbuilding countries like China, South Korea, and Japan are overwhelmed, prompting many foreign shipowners to place orders in Vietnam.

“We’ve received numerous requests from domestic shipowners for bulk carriers ranging from 6,000 to 30,000 tons, as well as offers from international clients. However, our current capacity doesn’t allow us to accept any more,” Mr. Rung noted.

A 14-vessel offshore wind service fleet being built through a partnership between Ha Long Shipbuilding Company and Damen Group (Netherlands) is one of the most advanced and technically complex projects ever undertaken in Vietnam. Three vessels have already been launched, with more in production.

Ha Long Shipbuilding Company, in collaboration with Damen Group (Netherlands), is building offshore wind service vessels. (Photo: Viet Hung/Vietnam+)

According to Mr. Nguyen Tuan Anh, General Director of Ha Long Shipbuilding Company, the company is also building a 120-meter overnight cruise ship, a cable-laying vessel, a 5-star passenger vessel, and a 45,000-ton bulk carrier for both domestic and international clients.

“With the current workload, we’re covered until 2027 and unfortunately have to turn down many offers despite high demand,” Mr. Tuan Anh admitted.

He emphasized that Ha Long Shipbuilding plans to continue developing high-value products such as cruise ships, oil tankers, and cargo vessels for the 2027–2030 period.

Launching Offshore Wind Service Vessels for Dutch Partner

Offshore wind service vessels are highly complex, equipped with advanced designs and technologies that play a crucial role in supporting offshore wind projects.

Mr. Nguyen Ba Son, Deputy General Director of Bach Dang Shipbuilding Company, stated that the firm is building oil/chemical tankers, LNG carriers for export to Italy, and general cargo ships.

By the end of this month, the company will deliver an LNG carrier with integrated tank systems. Additionally, a 9,300m³ oil/chemical tanker is scheduled to be launched in early June and delivered in October. Two 6,600-DWT cargo ships are expected to be completed by year-end.

“Our shipbuilding orders are scheduled through 2027 — a far cry from the hand-to-mouth days of the past,” Mr. Son remarked.

Vietnam Capable of Building Ships on Par with Europe

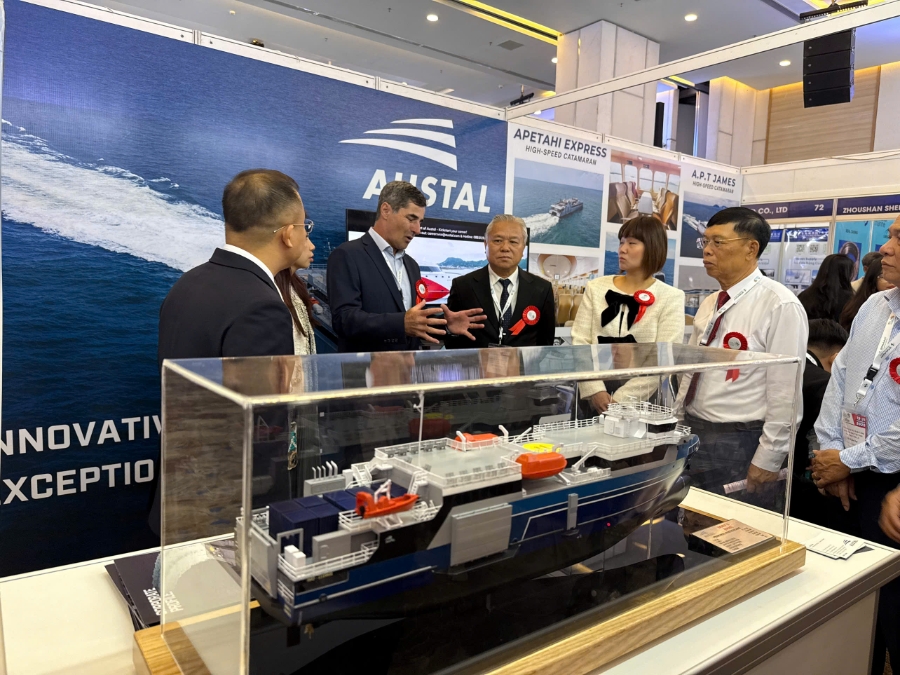

At the Vietship 2025 International Shipbuilding Technology Exhibition held in early March in Hanoi, numerous contracts and agreements were signed with both domestic and international partners, with total estimated value reaching $60 million. This demonstrates the capacity and global standing of Vietnam’s shipbuilding industry.

Mr. Willem, Executive Director of Windcat (a subsidiary of CMB.Tech and the vessel owner), after inspecting the three offshore wind vessels built by Ha Long Shipyard, affirmed that their quality is on par with similar vessels built in European shipyards.

He added that although these vessels are designed for offshore wind power projects, they can be adapted for all offshore energy ventures, representing a significant market opportunity.

“The timely launch of the third offshore wind service vessel highlights Ha Long Shipyard’s reliability and strengthens Vietnam’s position in the international shipbuilding arena,” Willem affirmed.

Thanks to cooperation with foreign partners, Song Cam Shipbuilding Company has modernized its production lines and workforce, enabling the construction of highly complex vessels.

Mr. Dam Quang Trung, Director of Song Cam Shipbuilding JSC, stated that in 2020, Damen Group (Netherlands) sent experts to assess the yard’s capacity and concluded that the yard could produce 25–27 vessels annually.

Vietnam’s Opportunities and Competitive Edge in Global Shipbuilding

Vietnam’s shipbuilding industry is benefiting from favorable macroeconomic conditions and global market trends. However, operations still have room for optimization through investment, workshop reorganization, and procedural improvements.

In 2024, the company successfully delivered 41 ships, a record figure for both domestic and international markets.

The Song Cam Shipbuilding Company has successfully built some of the world’s most complex types of vessels. (Photo: Viet Hung/Vietnam+)

“Specializing in high-tech small vessels like tugboats and high-speed boats, our top priorities must be workforce training and technology investment. Without continuous innovation, we risk falling behind,” Mr. Trung emphasized.

Recently, Bach Dang Shipbuilding also became a pioneer in Vietnam by successfully building an independent LNG storage tank on a 4,500m³ LNG carrier for export to Italy. The tank, made of high-grade steel and welded using advanced techniques, can withstand high pressure and maintain a cryogenic temperature of minus 100°C.

“Notably, Vietnam also handled the tank design. This LNG carrier, with a construction complexity 2–3 times that of conventional ships, marks the first time Vietnam has built such a vessel,” Mr. Nguyen Ba Son of Bach Dang Shipbuilding proudly shared.